Superior printing quality

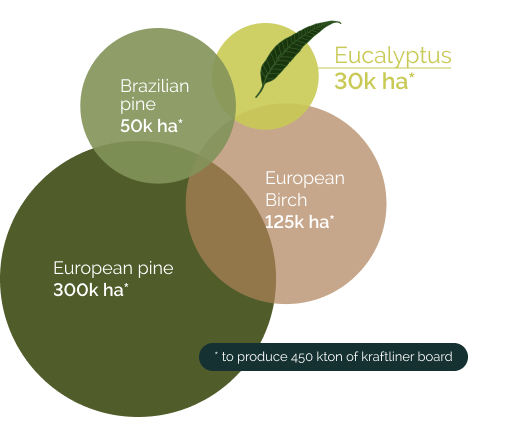

The Eukaliner® fiber composition associated to a state of the art equipment is responsible for a more homogeneous surface and a better printing quality of the product.

eucalipto 100/m

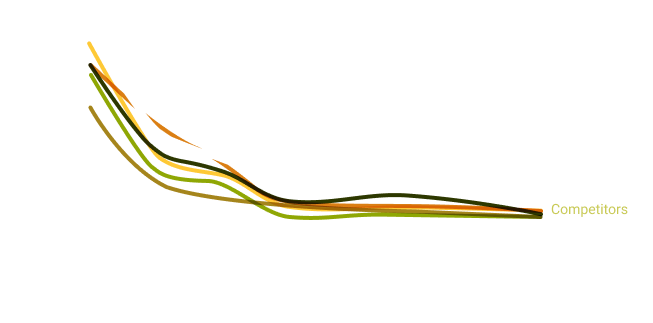

pinus 100/m